Reverse Engineering & CAD Reconstruction

At Shape Fabrication, we bring obsolete or undocumented parts back to life as precise digital assets. Using advanced scanning technology and expert CAD reconstruction, we deliver editable models ready for redesign, reproduction, or future innovation.

Beyond the blueprint

Whether you’re looking to recreate legacy parts, optimize tooling, or develop accurate models for quality control, we deliver solutions that fit your budget and timeline while meeting the highest industry standards.

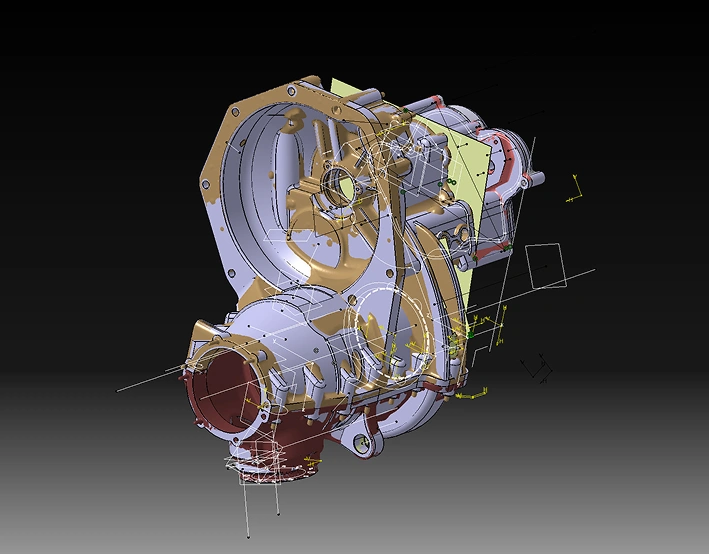

CAD reconstruction from deformed, worn out physical object (mold casting from magnesium alloy), adjustments for modern milling techniques

Our Capabilities:

We apply the right approach for every project, balancing accuracy, complexity, and budget.

Applications

Our reverse engineering services support a wide range of applications. We help customers reconstruct legacy parts with no existing documentation, redesign and optimize tooling such as jigs and fixtures, and develop accurate CAD models of assemblies for integration into new systems. Reverse engineering also supports rapid prototyping, digital archiving, and quality control by comparing manufactured parts against design intent. Whatever the application, our models empower smarter engineering decisions.

Hybrid Modeling

Many industrial components require a mix of freeform and geometric features, which is why we specialize in both NURBS surface modeling and parametric, feature-based CAD reconstruction. By combining precise surface modeling with solid geometry and editable design history, we create digital twins that balance functional accuracy with full CAD editability.

As-built vs Design-intent Models

Every project is unique, which is why we offer both “as-built” and “design-intent” models. As-built models capture the exact current condition of a part imperfections, wear, and all ideal for maintenance and replacement. Design-intent models, by contrast, reconstruct the original engineered geometry, delivering a clean, idealized version optimized for re-manufacturing or improvement. This flexibility allows us to tailor outputs precisely to your business needs.

Output Data Types

From raw scans to advanced CAD, we deliver models in the format best suited to your project. Point clouds and meshes provide fast, visual geometry; NURBS surfaces and hybrid models recreate freeform and analytic surfaces with accuracy; parametric, feature-based CAD models rebuild the full design history, making them editable. This spectrum of modeling options allows you to choose the right balance of fidelity, usability, and downstream compatibility.

Magsafe product collection

Industry:

Furniture

Country:

Poland

Scope of services:

Artificial lung for testing diving equipment

Industry:

Deep diving equipment

Country:

Poland

Scope of services:

Suspension kit for vintage Alfa Romeo rally cars

Industry:

Automotive

Country:

Sweden

Scope of services:

Pie making machine

Industry:

Gastronomy

Country:

Poland

Scope of services:

Magsafe product collection

Industry:

Furniture

Country:

Poland

Scope of services:

Artificial lung for testing diving equipment

Industry:

Deep diving equipment

Country:

Poland

Scope of services:

Suspension kit for vintage Alfa Romeo rally cars

Industry:

Automotive

Country:

Sweden

Scope of services:

Pie making machine

Industry:

Gastronomy

Country:

Poland

Scope of services:

CASE STUDIES

Customer-centric services with partnership commitment

Irrespective of the size of your order or the duration of our collaboration, we consistently uphold the highest standards of professionalism and communication.

See how we transform the challenges and ideas our clients bring to us into valuable solutions.

We'd love to talk about

your project

If you have any questions, please feel free to contact us.

We always try to respond within 24 hours.