Customer: Charlie’s Pie Shop

Country: Poland

Pie making machine

Customer: Charlie’s Pie Shop

Country: Poland

Industry: Gastronomy

SCOPE OF SERVICES:

MATERIALS

SCOPE OF SERVICES:

MATERIALS:

Customer background

Meet Nick, the visionary behind one of Krakow’s most esteemed hamburger restaurants. Wishing to diversify his culinary offer, he added delicious meat pies to his menu. Even though he already had a machine for making pies, its limited capabilities pushed Nick to buy a second one. Unfortunately, the company that made these devices was no longer in business.

Nick had an idea: if he couldn’t purchase another machine, perhaps he could locate someone willing to build a new one from scratch using the model he already had. While searching the internet for a suitable contractor, Nick eventually discovered our website.

The challenge

The primary challenge in this project was the fact that Nick used the device in his daily work. On the other hand, we needed to disassemble the device to understand its exact construction and create an accurate 3D model based on the measurements of individual elements. As his restaurant was located near our headquarters, we reached an agreement with him to carry out the entire process between the closing and opening hours of his restaurant.

We have prepared a two-stage appraisal: one for the model preparation and another for the production valuation (as the next step). Nick, content with this arrangement, gave us the green light to proceed.

Project process

Nick entrusted us with his machine after restaurant hours on a weekday. Aware that we would be closely studying the device, Nick also requested us to determine whether there was room for enhancing the machine to produce larger pies with greater accuracy. Our team worked overnight to carefully measure and create a precise 3D model based on the machine’s dimensions. Once the model was ready, we reassembled the machine, ensuring its perfect functionality. Nick reclaimed his machine the next day, just in time for his restaurant’s opening.

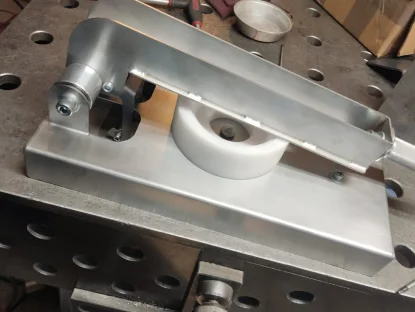

With the model fully prepared, we made the upgrades Nick asked us to make. Laser-cut and bent metal sheets formed the structure. We sourced top-grade food-safe screws and CNC-turned plates to craft components from food-grade plastic. These specialized plates played a pivotal role in pressing the dough into perfect pies. After rigorous testing and minor adjustments, the machine was ready within a two-week timeframe.

Effects of cooperation

Nick’s delight with the completed machine was palpable in the air. The streamlined pie-making process and the machine’s efficiency left him thoroughly satisfied. In the meantime, we also produced some spare parts for the device at his request. The success of this project augmented the strong foundation of our partnership. As Nick’s culinary ventures continue to flourish, we look forward to further collaborations.

“I discovered Shape Fabrication on Google. Initially, I had concerns about the parts, but our collaboration proved highly valuable. After my original manufacturer closed, I needed a second device and several new parts to continue production. Communication and involvement were satisfying. The final products exhibited high-quality with precise workmanship. I anticipated adjustments, but everything was perfect.

The reasonable cost made it an attractive deal. I look forward to working with them again and highly recommend their services to other entrepreneurs, primarily for the exceptional quality of workmanship.”

Nick Eltringham

CEO

Charlie's Pie Shop