Customer: MODevelopments

Country: Sweden

Suspension kit for vintage Alfa Romeo rally cars

Customer: MODevelopments

Country: Sweden

Industry: Automotive

SCOPE OF SERVICES:

MATERIALS

SCOPE OF SERVICES:

MATERIALS:

Customer background

Dennis Mollberg, the CEO of MODevelopments, is an experienced engineer and automotive mechanic from Sweden who has always dreamed of establishing a company that produces specialized parts for both classic and modern performance cars used in motorsport, which is also his true passion. With a custom suspension design ready, he began searching for the right contractor to bring his idea to life.

The challenge

Due to the nature of the project, Dennis tried to find a contractor who would have experience in motorsports and who could consult and potentially enhance his project based on own experiences. He wanted not only to ascertain if his project would meet all his expectations, but also to verify whether we could deliver high-quality final parts using techniques such as welding, machining, and coating.

He discovered our company, Shape Fabrication, through a Google search and after exchanging a few emails, we scheduled a phone call to discuss project details.

Project process

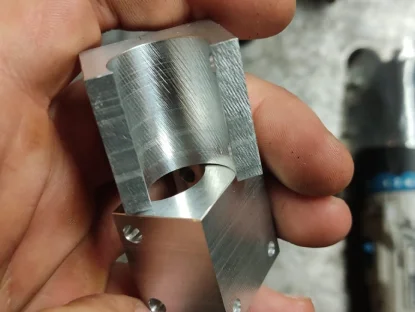

On our end, the task involved validating and developing a prototype based on the project file, followed by the production of 20 complete suspension kits for classic Alfa Romeo cars. After discussing the entire project and understanding all the preferences of our customer, we identified suitable contractors from our partner network to create specific elements and prepared a comprehensive quotation. The price was swiftly accepted by Dennis, enabling us to commence work.

During the validation of the project file, we identified several elements that, in our view, could be optimized. We’ve recommended adding a welded piece to box out the area where the ball joint is attached. That change significantly increased durability.

Based on the design changes approved by Dennis, we initiated the production of single prototype element to send it to him for testing. To meet the challenges of the project, we not only performed precise TIG welding (ensuring aesthetics, durability, and functionality), but we also had to address the issue of color selection.

The colors from the RAL palette didn’t fully meet Dennis’ expectations. After becoming acquainted with the exact effect he aimed to achieve, a helpful partner experienced in varnishing and painting surfaces came to our assistance. He suggested a method similar to that used in aluminium wheel refurbishment, with a slight color variation. The outcome was impressive!

After two months of intensive testing, Dennis came back to us with the results of his observations and with the conviction that the product would meet his design and functional expectations. We received the green light to produce all 20 kits.

Effects of cooperation

Upon receiving the finished kits, Dennis was highly satisfied with both the quality and aesthetics of the execution. He proudly showcases his accomplished project in a video clip promoting all his products. We continue our collaboration with Dennis to this day and maintain regular contact, thanks to the relationship we established during this project.

Our partnership with MODevelopments AB serves as an example of our commitment to providing suitable solutions that meet our clients’ requirements. By delivering high-quality products, efficient communication, and valuable engineering insights, we contribute to the success of our customers and foster long-lasting partnerships.

I found Shape Fabrication when I was searching on the web. I needed a partner for small series production of cnc machined, laser cut and welded parts. When I contacted them they had previous experience with the kind of parts I needed which was a very important factor for me. They make sure that there are no loose ends and the machining, welding, precision and surface treatment is perfect and this with no added cost over the competition!

The parts also arrives on time and very well packaged. All this is the reason I keep ordering from and can recommend Shape Fabrication. They are also very good at English!

Dennis Mollberg

CEO

MODevelopments AB