Customer: Xdeep

Country: Poland

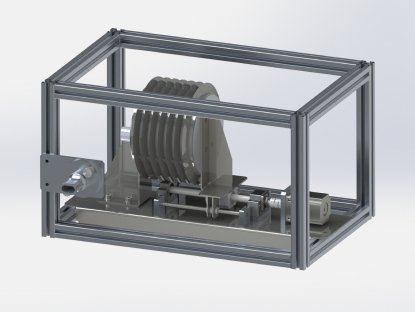

Artificial lung for testing diving equipment

Customer: Xdeep

Country: Poland

Industry: Deep diving equipment

SCOPE OF SERVICES:

MATERIALS

SCOPE OF SERVICES:

MATERIALS:

Customer background

Xdeep, the world’s leading manufacturer of deep diving equipment, discovered us on an industry internet forum. They approached us with an ambitious idea for a project called “Artificial Lung.” They had a rough idea of how they envisioned the device, which was meant for testing diving equipment by subjecting it to numerous cycles, thereby enhancing the quality and safety of Xdeep’s products and further elevating their international reputation.

The challenge

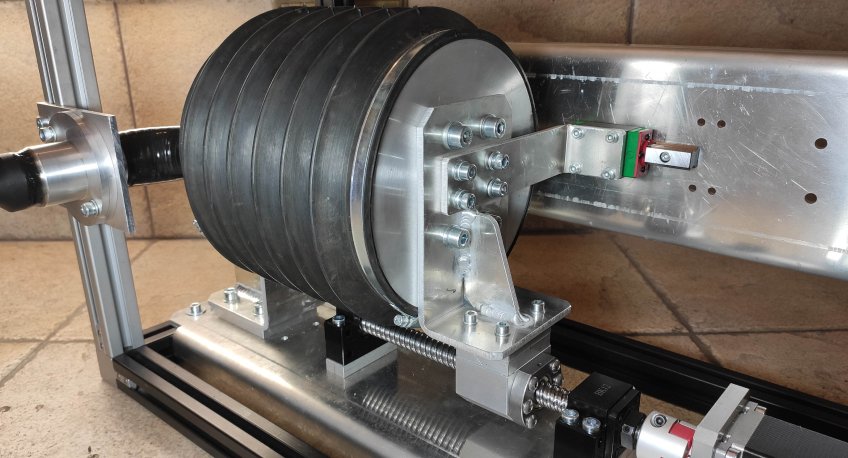

The biggest challenge was to construct the machine in a way that simulates the breathing of an adult man as faithfully as possible, placing the greatest emphasis on the volume of inhaled and exhaled air and the speed of breathing itself. Since the device was intended for intensive test cycles, it needed to be characterized by a fairly simple and reliable construction.

After a series of conversations and the collection of all the guidelines and suggestions, we presented the client with a comprehensive valuation divided into two stages: design and execution.

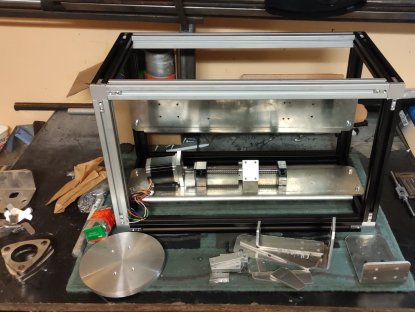

Project process

After the customer accepted the quote, we immediately began the design process. Due to the highly conceptual beginning of the project, we opted to utilize the Agile work methodology in its initial phase. By concurrently designing and gathering comments and feedback from the customer, we were able to develop the first version of the machine in a relatively short time.

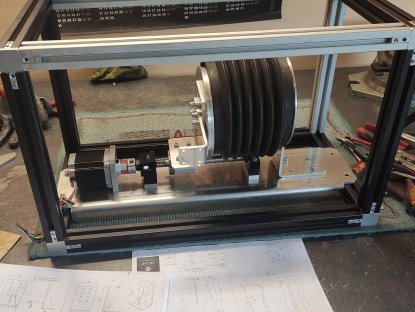

We assumed that the rate of breathing would be regulated by a stepper motor, while the volume would remain constant and could be adjusted based on the type of rubber bladder used in the device. In about two weeks, we presented the client with preliminary designs and results. After a few more adjustments, we were able to create a device that fully met their requirements.

Thanks to the fact that during the design stage, we planned the entire production process simultaneously, everything progressed swiftly and efficiently. We were aware of which elements would be more advantageous to purchase from the market and which ones to outsource to our subcontractors. Upon completing all the necessary components, we proceeded with the assembly and testing of the device.

During the performance testing stage, we identified areas for improvement in several components. Following the final adjustments, the device operated precisely as our customer had anticipated. Within three weeks of project approval, we delivered a fully operational device to the customer.

Effects of cooperation

Xdeep was very pleased with the final version of the device. They expressed surprise at the reasonable price of the entire service, much to our satisfaction, as the project was both intriguing and challenging. Overcoming all of the project’s challenges brought us the greatest satisfaction, and receiving positive feedback from the customer is exactly what we strive for in this industry.

Due to our successful cooperation, the client subsequently approached us with numerous requests in the realm of 3D modeling for new prototypes, as well as designing and manufacturing several test devices using 3D printing technology. Additionally, we collaborated on the creation of a larger production automation machine, leveraging our experience in automation field.

“We found Shape Fabrication using a specialized online forum for CAD engineers. We needed a company that could design, test and manufacture a machine which would serve as an “artificial lung” for testing deep diving equipment. Thanks to the expertise and dedication of the team we had the device ready for use within several weeks and the pricing was competitive. Communication with the engineering team of Shape Fabrication as well as the quality of the end-product fully met our expectations.

I can highly recommend Shape Fabrication to other companies who are in need of a one-stop-shop for industrial prototyping and manufacturing.”

Piotr Czernik

CEO

Xdeep